2025 NSF Certified Compact Terminal Water Descaler for Maintenance Free Home Use

A calcium carbonate layer of just 0.8–1mm can increase energy consumption by 16%, and when it reaches 3mm, energy consumption can spike by 40%. Limescale also accelerates equipment corrosion and poses serious safety risks.

Traditional chemical descaling methods are highly polluting, while electromagnetic techniques consume excessive energy. SAAS pure physical technology, based on innovative materials, overcomes these limitations and sets a new industry standard.

I. SAAS Core Technical Principle

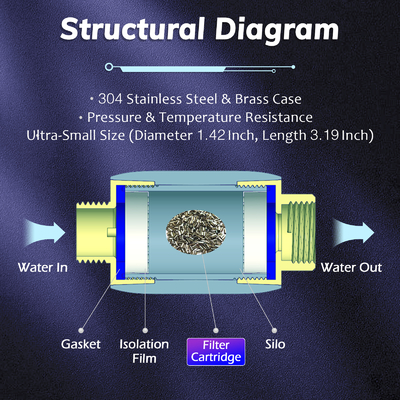

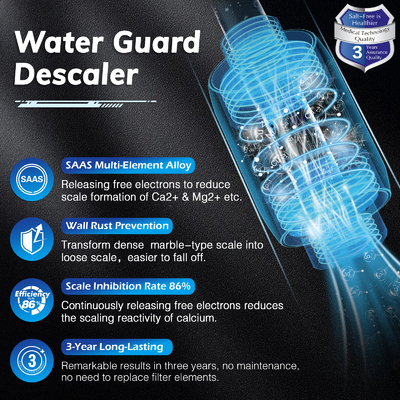

The SAAS copper-based catalytic material is a specially developed alloy catalyst, independently created by our team. It combines multiple metals such as Cu, Zn, and Ni with varying electronegativities. Through a sophisticated high-temperature smelting process, a uniform, columnar crystal structure is formed. This structure enables the material to release free electrons into fluid media and induce polarization.

Electron Polarization for Scale Inhibition:

Solvent molecules in the water are polarized, forming ordered dipoles and new scale-forming ion couples. These remain suspended, greatly reducing the likelihood of scale formation. At the same time, electrostatic adhesion to pipe walls is weakened, lowering calcium and magnesium deposition.

Crystal Structure Conversion for Descaling:

Dense “calcite” (marble-like) scale is converted into loose “aragonite” structures, gradually softening and detaching from the surface to achieve effective pipeline descaling.

Electrochemical Anti-Corrosion and Antibacterial Effect:

A 500μm protective compound layer isolates metal from fluid contact. Microcurrents inhibit bacterial division, with lab testing showing a 99.99% inhibition rate for E. coli.

Long-Lasting Performance:

The SAAS household descaler operates continuously, without monitoring or intervention. After installation, it significantly reduces corrosion and blockages, extending equipment lifespan. Treated fluid maintains descaling capability for up to 72 hours.

II. Full-Scenario Application Value

II. Full-Scenario Application Value

1. Household Equipment Protection

-

Water heaters / washing machines: Reduce energy consumption by 20–30%, prevent clogging and equipment failures.

-

Central air conditioning / floor heating systems: Improve energy efficiency by 20–30%, saving approximately 1000 RMB annually.

-

Solar water heaters: Avoid pipeline blockages and explosion hazards caused by limescale.

2. Industrial System Solutions

-

Boilers / heat exchangers: Lower heat transfer resistance, prevent pipe bursts, and reduce chemical cleaning costs.

-

Cooling water circulation systems: Minimize microbial growth and reduce maintenance expenses.

-

Oilfield / thermal network systems: Ensure smooth pipelines and enhance energy transfer efficiency.

III. Technical Advantages

-

High Efficiency & Energy Saving: Investment recovered within 3–6 months; scale inhibition rate depends on the amount of filtering media used.

-

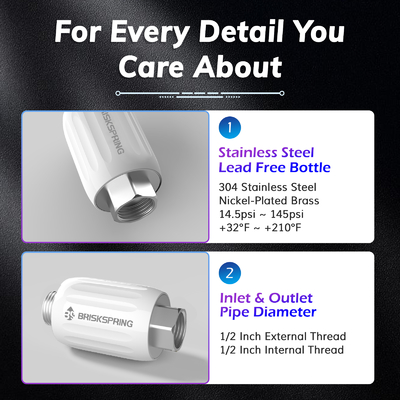

Easy Installation: Quick-connect design with no pipeline modification required; compatible with standard fittings.

-

Safety Certification: Tested to international standards including SGS and NAF; materials are safe and reliable.

-

Long-Lasting Durability: Dual-mode design (turbine + filtering media) provides a service life exceeding 10 years.

SAAS technology transforms “passive descaling” into “active scale prevention” through material innovation, offering complete physical protection for household and industrial equipment and ushering in a new era of green, energy-efficient solutions.

SAAS technology transforms “passive descaling” into “active scale prevention” through material innovation, offering complete physical protection for household and industrial equipment and ushering in a new era of green, energy-efficient solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!